Unique knowledge accompanies every order

To achieve the best results in the printing process or in packaging manufacture, you need not only a high quality base material, but also knowledge about how to use that material in the best possible way. Brand owners, designers, packaging developers and printers all contribute their own specific knowledge and experience to help optimise the product’s properties and functions throughout its lifespan. For this reason, hands-on knowledge about the special properties of paperboard is also required.

Our service offer

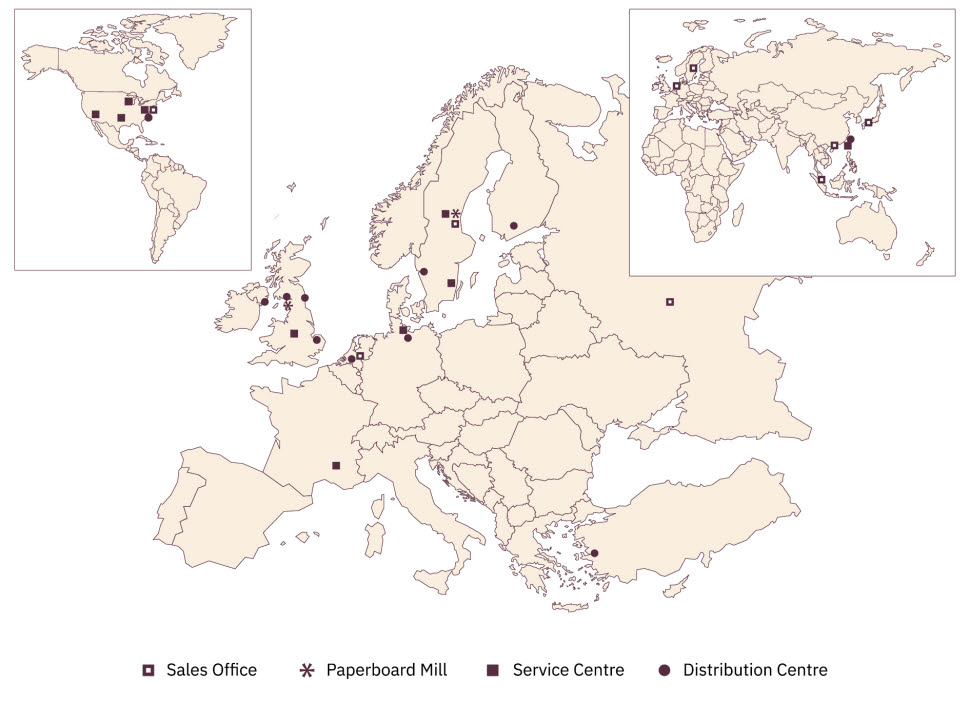

All sales of Holmen Iggesund’s products in Europe are coordinated at our sales office in Amsterdam. We also have sales offices in Singapore, Hong Kong, Japan

and the United States. We have organised our people, technology, and systems to suit your priorities and offer complete commercial and technical customer support.

We know that customers’ needs constantly evolve, and market conditions are ever-changing.

The service we provide is based on some simple principles:

- Locally based account managers and technical service managers. Account coordinators in the sales office in Amsterdam speak different European languages.

- Sheeting facilities close to our main markets, as well as at our mills, ensure the rapid delivery of small orders.

- Storage facilities close to our customers.

- A wide network of selected merchants supplement the sales network.

Quality assurance

We have implemented Quality Assurance Systems to maintain our product quality and to meet customer needs and expectations. At our mills we have certified quality assurance systems in accordance with ISO 9001. We welcome customer audits to approve and further develop our quality system. Product specifications and contracts are essential elements for ensuring that we have agreements between our customers and ourselves, which meet the need for clear, joint understandings about product quality. We believe that quality has a broader meaning and includes how the paperboard is made and how it impacts our planet. Therefore, our paperboard is also certified according to ISO 14001 and ISO 45001.

Accredited laboratory

Our Laboratory for Sensory and Chemical Analyses is accredited for sensory measurements by the Swedish National Accreditation Authority, SWEDAC. This guarantees that tests are objectively carried out using approved and tested methods. The laboratory performs sensory analysis using statistical evaluation and chemical analysis using a gas chromatograph and mass spectrometry. It has unique equipment for taking gas samples at room temperature and has developed methods for measuring the effects of aromas on packaging material/permeability. Please note that the chemical analyses are not accredited. The laboratory safeguards the taint and odour neutrality of raw materials, the baseboard and the final products. Third parties often consult the laboratory when investigating taint and odour problems.

Accreditation number: 1740 ISO/IEC 17025.

Product safety

The essential purpose of packaging is to ensure the hygiene and quality of the packed product. We control the entire pulp and paperboard chain production so that we can supply paperboard products which meet strict standards for hygiene, barrier functions, and taint and odour neutrality. All materials used in the making of our board are approved for food contact in accordance with current regulations in different countries. To ensure that we are providing the correct product and product safety documentation we must know the intended final application. If your specific applications require productsafety certificates or if further information is needed, please contact your local Technical Service Manager

Compliance, accreditations and awards

Packaging in general, paperboard and paperboard-making processes are all subject to environmental attention. As a paperboard supplier, we take responsibility for the environmental impact of our products all the way from the sourcing of raw materials through our manufacturing processes.

Environmental management systems are implemented at all our mills (ISO 14001). The Holmen Group’s forest management routines are approved in accordance with the FSC® (C110018/C008588) and PEFC™ (PEFC/05-33-105) standards as well as certified in accordance with the ISO 14001 standard. Both our mills hold chain of custody certifications (CoC) in accordance with FSC® and the Iggesund Mill also holds CoC certification with PEFC™. This enables our certified customers to be part of the chain. . Our aim is that our processes will meet environmental requirements with good safety margins and we ensure that our products are safe for handling and use. Both mills operate in accordance with the energy management system standard ISO 50001 and the safety management system ISO 45001.

Packaging waste and associated landfill issues are of major concern in some countries. For a long time, used paper and paperboard have proven to be easy to recover – both as a raw material for recycled fibre products and also for energy recovery.

Holmen Iggesund’s energy use is based on biofuels and we have initiated programmes to further reduce the use of fossil fuels, thereby reducing fossil carbon dioxide emissions.

Paperboard has a low carbon footprint compared to other packaging materials. The raw material, timber, is harvested from managed forests that absorb carbon dioxide and emit oxygen. We measure our carbon footprint according to CEPI guidelines and updated data can be found at iggesund.com/certificates.

Holmen has reported to the CDP Climate Program since 2007 and also to the CDP Forest Program since 2013. Surveys over the years have shown that Holmen has good management in place and a strategy to reduce the negative impacts of climate change. In the evaluation of forest management, Holmen has been placed in the group for good leadership that ensures sustainable use of the forest’s resources for several years now. In the 2021 results, Holmen scored highly in two categories: Climate Change A- and Forests A-.

The Holmen Group has been part of the UN Global Compact and its corresponding Nordic network since 2007. Each year the group reports its sustainability work according to the ten principles of the Global Compact. The principles relate to human rights, social conditions, the right to establish trade unions, environmental responsibility and anti-corruption.

As members of the UN Global Compact, Holmen annually reports a “Communication on Progress” (COP) that describes how its work with Global Compact’s principles for responsible business practice is progressing.

Twice in the last decade, Holmen has been included in the Corporate Knights index over the 100 most sustainable companies in the world, Global 100.

The Carbon Disclosure Project (CDP) is the name of an international federation that in 2016 represented 827 institutional investors with assets totalling around SEK 900 billion. CDP seeks to encourage companies around the world to reduce their impact on the climate and nature’s resources, and it presents an annual report on the outcome of its work. As a result of its energy investments and the consequent fall in carbon dioxide emissions in 2014, Holmen qualified for the A list on the Climate Performance Leadership Index. The global index lists 187 companies that have been shown to have an excellent strategy for reducing climate change.

For a complete and updated list of certificates, go to iggesund.com/certificates.