The fibre composition varies for each layer in the construction. Fibres are selected based on shape and length and treated in different ways to tailor the paperboard construction to the intended use. The benefit of this multi-layered SBB compared to competing single- and dual layer products is the unique possibility of optimizing the surface fibre layers to form an excellent base for coating. The coating is applied in two or three steps to meet the smoothness demands of printing and foiling applications.

The advantage of a multi-ply construction compared to a single ply one is that the different layers can be composed to optimise board characteristics such as stiffness and strength, thus ensuring both productivity in converting operations and good function in the end product.

Invercote products are widely used for picture postcards, high-quality brochures and book covers, and the packaging of cosmetics, perfumes, chocolate, pharmaceutical and tobacco products. Invercote is manufactured from fibre of known and traceable origin and produced at a site where pulp production is integrated with the paperboard mill. This combined with the inherent stability of our chosen manufacturing process ensures a repeatable and predictable performance of the product in converting and use.

Invercote in use

The fully coated printing surfaces of the Invercote family are designed to meet the highest demands of image reproduction in printing and surface treatment methods such as hot-foil, foil- and film application. The coating composition is adjusted in two different general directions for the product family to satisfy printability requirements, primarily of offset-litho and gravure printing. Inks on the market intended for use on fully coated surfaces can be used on the full range of Invercote products with the exception of Invercote Albato, where considerations need to be taken to adjust to the glossy and somewhat closed surface of the product when applying absorption-drying ink types. Invercote can be printed in offset-litho, gravure, flexo, screen, and selected digital printing processes. Invercote products are not suitable for web-offset or heatset printing.

Adjustments in the prepress operation and the choice of ICC profiles can be done in the same way as for a fully coated fine paper. When performing repro for delicate work or if a major part of your production is running on Invercote, you may benefit from creating your own dedicated ICC profiles for Invercote in your selected process environment.

Invercote works well in most digital colour copiers and digital printing presses on the market today. Invercote is suitable for many digital printing applications, but due to the multitude of printing engines and the rapid development of both inks/toners and machinery, we recommend that you contact our technical service personnel for assistance.

Invercote can be sheet laminated over the print with cellulose acetate or oriented polypropylene (OPP) for a high gloss appearance.

Invercote’s strength and inherent consistent baseboard performance will support full speed printing and post-print production. Deep and narrow creases can be achieved as well as excellent deep and detailed embossing. The strength and toughness of the fibre network does, however, make it necessary to adjust tooling and its application in post-press converting (primarily cutting, creasing and embossing) to produce the best result. Recommendations for creasing are provided in this document. With regard to knife- and embossing tool geometry, we advise you to contact your supplier.

Invercote can be glued with both emulsion (water-based) and hot melt adhesives. With both types of adhesive, initial tack, fibre tear and secure mature bonds can be achieved over a wide range of speeds and conditions of use.

Creasing recommendations

Please observe that these are general recommendations and adjustments might be necessary in each case. For the products Invercote Albato and Invercote Creato we recommend the closest thickness. In general, Invercote, being a solid bleached board, gives good creasing and folding over a wide range of settings. In many cases the same tool combinations can be used for both MD and CD creases.

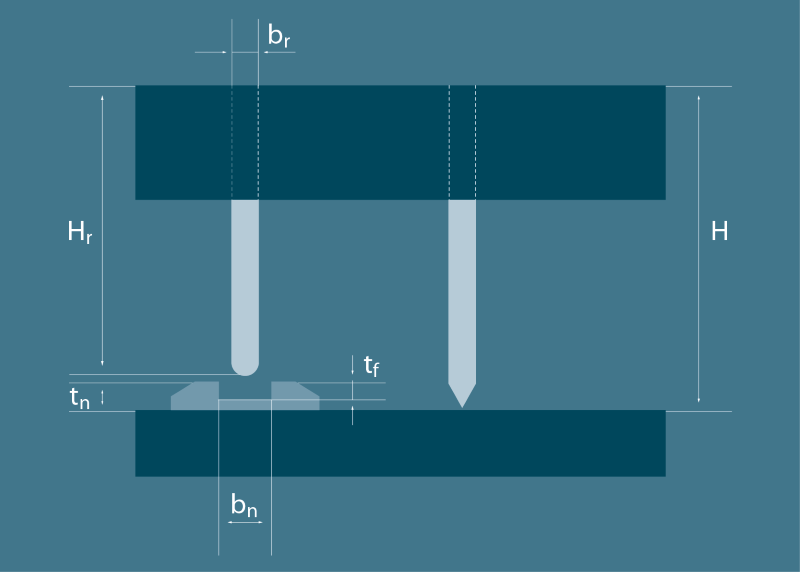

| Height of cutting rule, H=23.8 mm Groove depth, tf = tn – 0.1 mm | ||||

| Creasing rule | ||||

| Paperboard Thickness (µm) | Groove width, bn (mm) | Matrix thickness1), tn (mm) | Height, Hr (mm) | Thickness, br (mm) |

| 205 | 0,9 | 0,5 | 23.4 | 0,70 |

| 235 | 1,0 | 0,5 | 23.4 | 0,70 |

| 270 | 1,0 | 0,5 | 23.4 | 0,70 |

| 300 | 1,0 | 0,5 | 23,3 | 0,70 |

| 330 | 1,1 | 0,5 | 23,3 | 0,70 |

| 360 | 1,2 | 0,6 | 23,2 | 0,70 |

| 395 | 1,2 | 0,6 | 23,2 | 0,70 |

| 435 | 1,3 | 0,6 | 23,2 | 0,70 |

| 465 | 1,3 | 0,6 | 23,2 | 0,70 |

| 505 | 1,4 | 0,7 | 23,1 | 0,70 |

| 1) Matrix (Pertinax) | ||||