Why did you choose to go green?

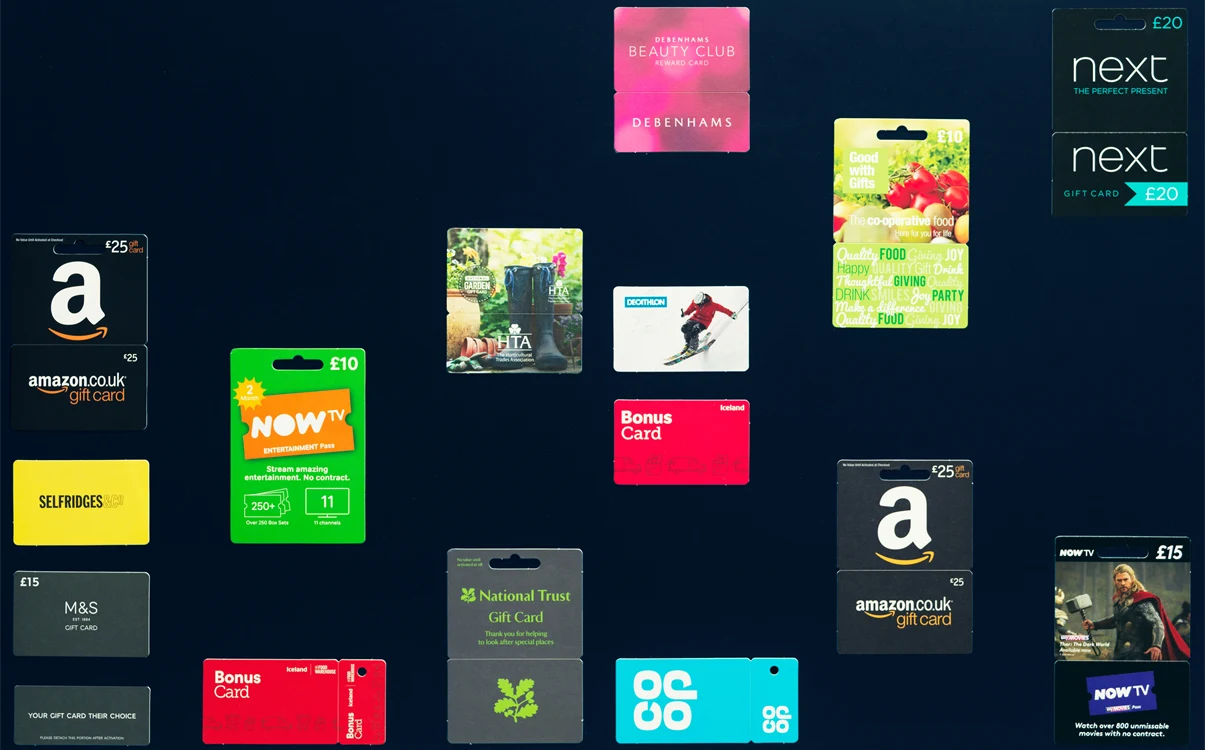

“In 2006 we helped launch the UK’s first third-party gift card mall in 650 Sainsbury’s stores. It became obvious that plastic was an over-engineered, expensive and slow-to-produce solution for a short-life product. It was also clear that plastics would soon become an environmental problem. We looked at a wide range of bioplastics and other alternatives but they all came up short in terms of their green credentials, cost and printability, so we looked at paperboard. To make paperboard a viable alternative we had to develop a ‘snap’ functionality to replicate the popular M6 card format with integrated hanging. We now own design rights to a number of ‘snap’ solutions for paperboard products.”

What makes paperboard cards a better choice than plastic ones?

“Typically a PVC gift card produces 66 g of carbon versus a paperboard card’s mere 2,1 g. And the paperboard we use is a feature in itself – the uncoated version has proved very popular with brands as they transition from plastic to paperboard. For years, our target was to create paperboard gift cards that replicated plastic but more recently, brands want to make a statement that their gift cards are now on paperboard. The uncoated version of Invercote Duo is the perfect substrate to achieve this.”

Who are your customers?

“We work closely with one of the world’s leading gift card issuers and processors. The brands they distribute include Xbox, Sony and Sky, who all use green gift cards, as well as numerous small and medium-size organisations. Paperboard is perfect for digital download products such as games and content, because the cards are only used once.”

Why do your clients choose green gift cards?

“For a lot of brands now, tackling the environmental challenge is becoming ever more important. Insurance company Aviva recently approached us to help them switch their temporary name badges from PVC to paperboard. We applied a gloss bio-laminate to coated Invercote Duo to replicate their PVC cards.”

You’ve experimented with paperboard cards?

“We’ve tested multiple substrates over the last 10 years, doing scientific and very simple experiments. We also recently tested the obvious limitations of paperboard in water. We compared three materials used in gift card production: two established ones plus Invercote Duo. After 20 minutes submerged in a bowl of water at room temperature, Invercote outperformed the others, as it did not delaminate or deform as the others did.”

What other items would you like to see switch from plastic to paper?

“Retail packaging is a far bigger problem than gift cards. We simply cannot afford to continue to be apathetic about our impact on the environment. Change needs to happen now or it will be too late. When I’ve spoken to sustainability managers at brands about gift cards, they say they’re focused on thousands of tons of packaging waste, and gift cards are a low priority. Packaging designers should consider the materials they use and their impact. There is a massive untapped opportunity for brands to leverage the positive consumer and stakeholder sentiment and PR that comes from switching to environmentally responsible alternatives.”

Why did you use Invercote Duo?

“Through testing and trialling, Invercote has proved to be the best material to date. It offers the thickness, rigidity and feel we know consumers want by using the 790 micron calliper (610 g/m², 790 µm, 31.1 pt). Not only does it look and feel almost identical to PVC when printed and cut to shape, but it also snaps in a similar way to PVC, providing a clean and high-quality finish. Invercote’s green credentials are also impressive.”